PRINTING TECHNOLOGIES

Flexographic Printing

Flexographic printing is very competitive for higher volume orders. We offer both water-based printing and full UV printing. We also have servo-driven printing capabilities, which reduces the loss of materials and lowers the setup time. Flexographic labels are highly versatile, and they can be applied on nearly all packages.

They can be printed on a wide variety of materials, including paper, shrink film, self-adhesive labels, aluminum foil, composite materials, etc. According to the application of the printed object, flexographic printing can produce self-adhesive labels, single aluminum foil labels, shrink mold labels, flexible packaging products, etc.You can find flexographic labels on just about any type of product.

Learn more

Up to 9-color printing

Custom color matching

Double-sided printing and multi-layer constructions available

Servo-driven printing available

In-house Esko/Dupont Fast Digital Plate Making Technology™

Vast array of cutting dies available, including special shapes and sizes

Cold foil and hot foil available

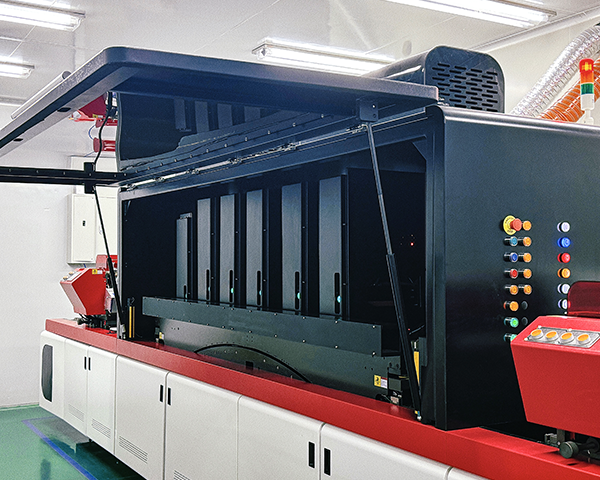

Digital Printing

Digital printing technology offers solutions and versatility that other printing methods cannot deliver. It's a rapidly developing technology that's changing the label industry. As new printers and technologies have emerged, digital printing offers the absolute highest quality.

Digital printing can be easily operates and highly efficient. It enables direct computer typesetting, modification and production. Printing inkjet prints directly, which eliminates plate charges, while giving us beautiful printing results such as excellent print quality and accurate color matching.

Learn more

Exact match proofs printed on the same material and equipment that will run your order

No plate or color charges

Seven color process printing for true Pantone® matching

Customization including variable data and images, bar codes, security features,and sequential numbering

Vast array of cutting dies available,including special shapes & sizes

Custom color matching

Shrink sleeves and flexible packaging options

Graphics printed with perfect registration of the utmost clarity and resolution

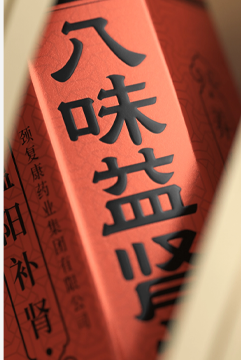

Letterpress Printing

Letterpress printing is an absolute amazing print method that has roots deep in history. In this method, a surface with raised graphics is inked while the blank parts are lowered. Under the printing pressure, the ink images will be pressed to the surface of a substrate like paper, metal stone blocks to reproduce an image in reverse. Letterpress printing is suitable for printing poster, books, packaging and other stationary products.

Learn more

It provides strong and vibrant color

Multi-color printing is available

Print quality comparable with digital

Ideal for small jobs

Can process different types of labels and more diversified or personalized jobs

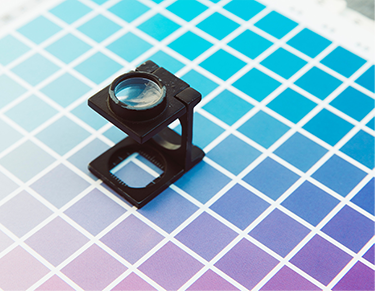

Offset Printing

Offset printing is a popular printing press technique, which transfers ink from a plate to a rubber roller, then onto a printing surface. It's used for mass production of custom printed boxes, magazines and other products due to it's high-quality and low cost.

Learn more

Faster turnaround and lower cost

Superior image quality; specialize in gradient color printing

Deliver best results in terms of detail resolution and accuracy; capability in micro printing, providing letters and graphics which may require magnification to see

Silk Screen Printing

Silk screen printing is a flexible way to help many products come to life on the shelves. Silk Screen Printing is a technique that involves utilizing a mesh pattern to a product surface, then pressing or pumping ink through the mesh openings and onto the product to produce the image.

Learn more

Long lasting and durable: suitable for long-term demonstration, the colors won't fade away as time goes by

Versatile: Suitable for all kinds of inks, and strong color intensity is guaranteed

A cost-effective way to create a unique look

Tactile and textured

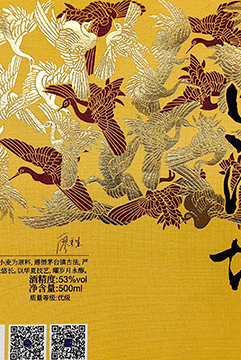

EMBELLISHMENT TYPE

Cold Foli

Hot Foil

Embossing

3D Hot Stamping

Shrink Sleeve Labels

UV Coating

Tamper Evident Void Labels

Double Peel Off Labels

UV Tamper Evident Labels

Color-Changing Labels

Reverse UV Varnish

Removable Labels

Glasses-Free 3D Labels

One ltem One Code Labels

Multi-Layer Labels

QUALITY MANAGEMENT SYSTEM

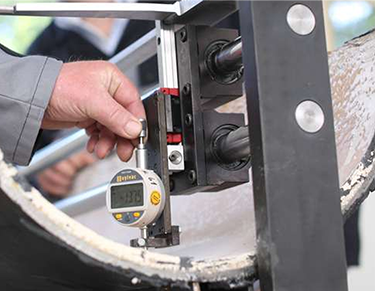

KB Printing has a comprehensive quality management system that focuses on preventative actions and continuous improvement. Our system is built upon ISO9001 certification. We have 100% quality control vision inspection technology. We utilise 17 automatic vision inspection technology from Israel and China, which installed on the printing machine for both online and offline inspection, as well as final slitting full inspection. This triple inspection ensures that the rate of non-conformance is low.

Additionally, We insist on batch control and traceability. We have a batch control system that identifies each label product we produce and also separately each job (batch) we print. Both codes are recorded on every roll and carton associated with that batch via our seal-off and carton labels. These codes can be matched through our manufacturing system to trace both backwards through the production and supply chain and forwards to our clients for complete traceability.

We regularly review our systems and have a program of internal, external and client audits. This guarantees that our print quality meets our clients' expectations from the beginning of the printing process.

LABORATORY

KB Printing has a laboratory to make sure that we rigorously screen new materials and products before launch, conduct comparison and quality control tests, and conduct quality investigations. Our team of expertise are responsible for conducting comparative and quality control tests on all new materials and products before launch, just to eliminating risk for our customers. At the same time, the laboratory will offer objectivity to assist with the speedy resolution of any problems.

Material testing e.g. adhesion, dispensing, moisture penetration

Establishing Laminate adhesion standards for Cold Pasteurisation

Transportation simulation including wet and dry abrasion

Environmental resistance e.g. Light, Steam, Heat, Water, Weather

Chemical resistance e.g. Oil, Plasticiser, Acid, Sea Water

Direct thermal print durability and image quality testing